GR7000 series is engineered for signage, automotive aftermarket, printing &cutting, etc. It shares most of the features of our GR8000 series while light in weight and more cost-effective.The GR7000 series is well applied to process vinyl stickers, reflective films, PPF, screen protectors, sandblast rubber stencil, photo-masking films, heat transfer materials, just name a few.

Static Electricity Free

Static interference is a big headache to cutters, while that is not the case with Gunner, as we eliminate it and have tested that year-round in different weathers.

Grating Ruler

Inevitably material surface is not level from point to point, the Grating Ruler is applied to measure the distance between blade tip and material surface, and the cutting depth is adjusted in every 0.01mm by the controller accordingly. Then the blade travels up and down as material surface goes to keep the same cutting depth at any position of the tool paths across the entire table. In short, Grating Ruler is of key importance for consistent cutting depth.

Advanced Tool Carriage

The tool carriage adopts the structure of sports car, using of silent voice coil motor makes it outstrip it’s rivals. The tool carriage is featured as fast, agile and no overheat for long-time non-stop operation. It is a leading tool carriage in the same field in China.

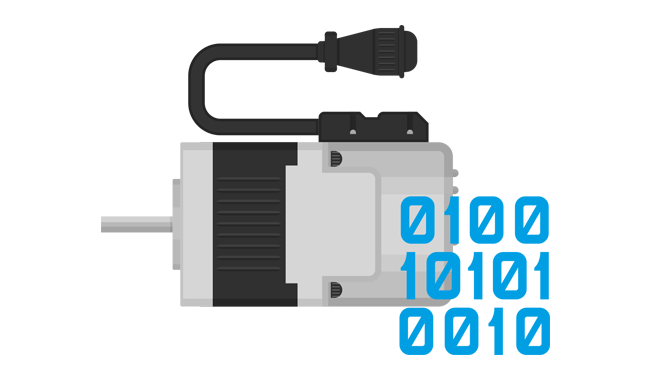

Servo Drive

Intelligent servos bring out smooth acceleration, big torque, precise cutting / plotting operation, excellent durability and volume production. Servos ensure the cutting plotter to run at Max. Speed: 600mm/s while the acceleration reaches 4000mm/ s².

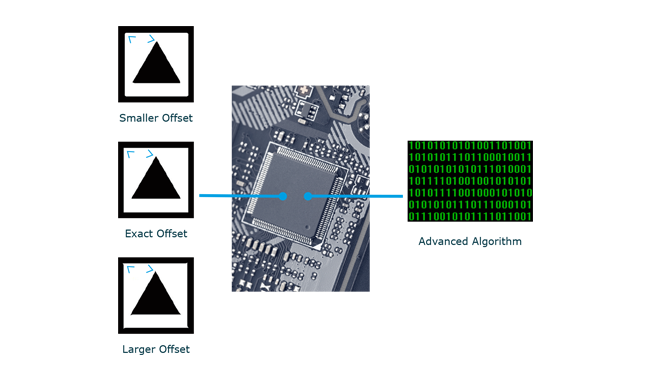

Making Blade-tip Compensation by Chip

Gunner makes blade-tip compensation with Chip instead of software, the cutter works with constant high precision no matter what kind of CAD / CAM software is applied.

Automatic Data Retrieving with Bar-code

One touch to find the cutting job out of those saved in the USB memory by scanning the printed Bar-code, while no need to connect to computer. Multiple jobs are processed automatically while production errors are eliminated.

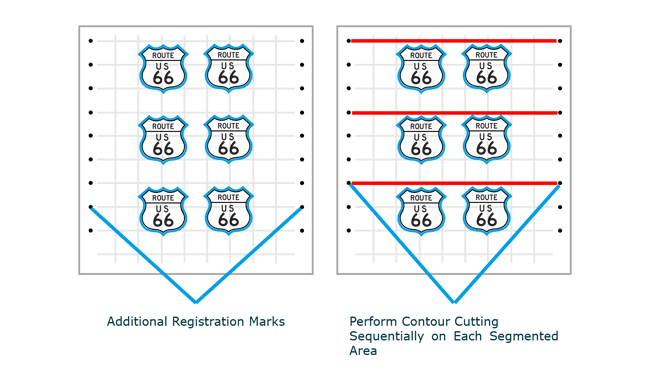

Segmented Area Cutting Operation

Additional registration marks are available for more precise axis alignment. Contour cutting is performed sequentially in each segmented area, which improves accuracy and tracking for heavier media or media that has been laminated.

Clean Smooth Edge Quality

The Grating Ruler and correspondent cutting force management deliver clean smooth edge quality, even for the most complex jobs. Pealing off the cutting piece/waste material easily can cut down workload greatly for the users. Advanced algorithm developed by Gunner eliminates the distorted, rounded and lifted corners obviously.

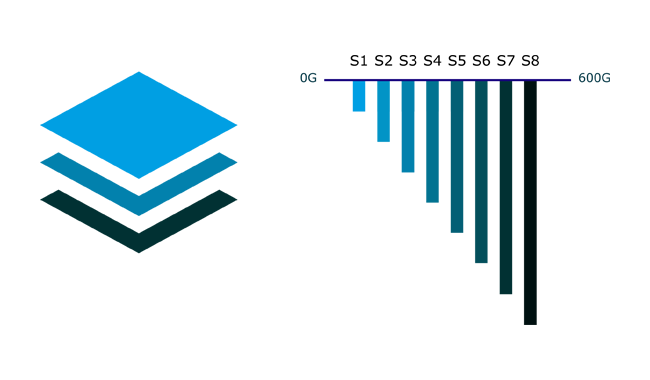

Cutting Force in 8 Step

With Gunner software, user is enabled to put different colors for different cutting paths, and set the processing sequence as color sequence. This is a important feature for cutting medias with multiple layers, which requires different cutting force in different layer.

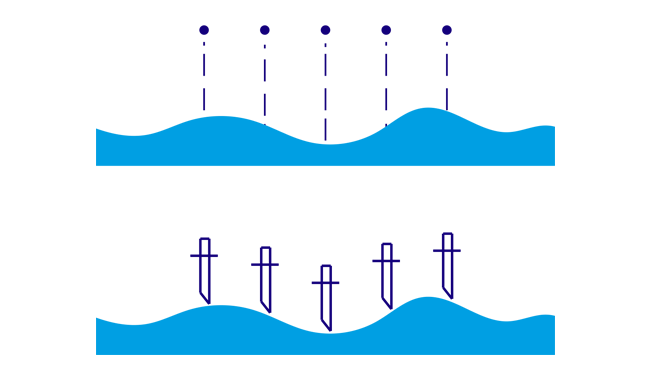

Dotted Lines Cutting

Dotted line cutting is applied for cutting medias with 2 layers typically and also kinds of paper. The feature asks for accurate control of cutting forces.

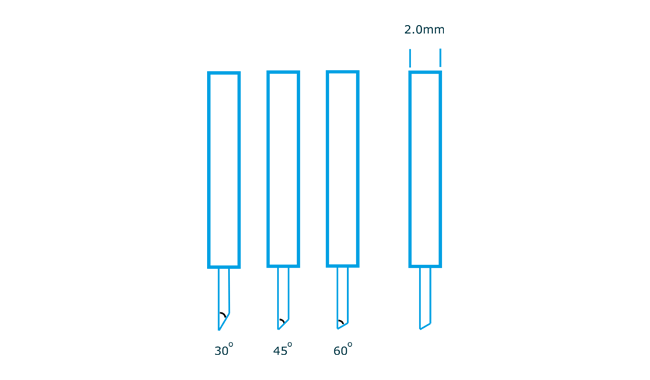

Series Cutter Blades Available

Angle: 30° / Φ2.0mm for prismatic reflective sheeting, thick media or small character Angle: 60° / Φ2.0mm for reflective film Angle: 45° / Φ2.0mm for PPF