GR7090F, a special purpose auto-fed flatbed cutting plotter for DTF industry with features optimized according to characters of material applied in the DTF field.

QR code scanner is available since 2024.

Super easy installation, one-key operation and high efficiency make GR7090 a right-hand man for DTF, Heat transfer apparel industries.

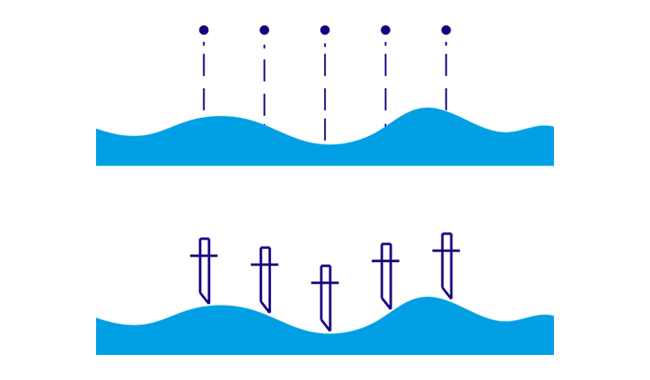

Grating Ruler

Inevitably material surface is not level from point to point, the grating ruler is applied to measure the distance between blade tip and material surface, and the cutting depth is adjusted in every 0.01mm by the controller accordingly. Then the blade travels up and down as material surface goes to keep the same cutting depth at any position of the tool paths across the entire table. In short, Grating Ruler is of key importance for consistent cutting depth.

Advanced Tool Carriage

The tool carriage adopts the structure of sports car, using of silent voice coil motor makes it outstrip it’s rivals. The tool carriage is featured as fast, agile and no overheat for long-time non-stop operation. It is a leading tool carriage in the same field in China.

Servo Drive

Intelligent servos bring out smooth acceleration, big torque, precise cutting / plotting operation, excellent durability and volume production. Servos ensure the cutting plotter to run at Max. Speed: 600mm/s.

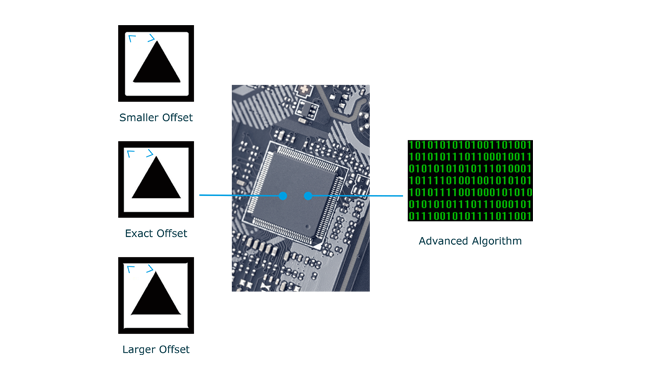

Making Blade-tip Compensation by Chip

Gunner makes blade-tip compensation with Chip instead of software, the cutting plotter works with constant high precision no matter what kind of CAD / CAM software is applied.

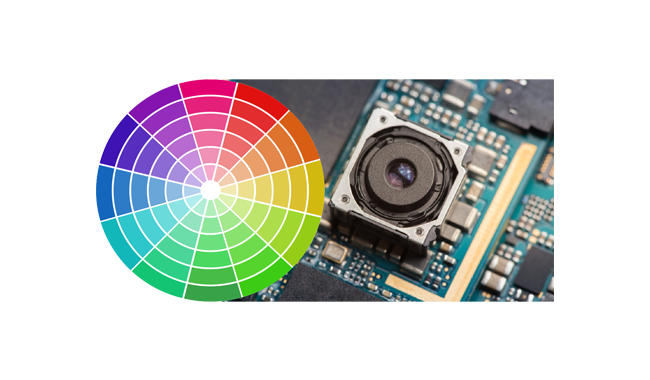

Fast Registration Marks Detection with CCD Camera

CCD camera detects the intricate die-less contours efficiently, problems caused by position error of human, poor quality printing are resolved. CCD camera is applied for wider varieties of colors.

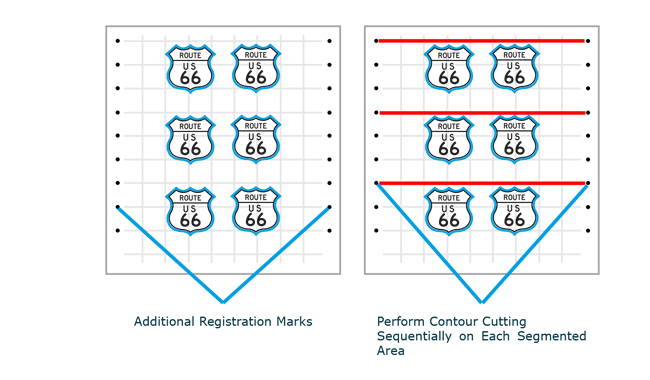

Segmented Area Cutting Operation

Additional registration marks are available for more precise axis alignment.

Contour cutting is performed sequentially in each segmented area, which improves accuracy and tracking for heavier media or media that has been laminated.

Automatic Data Retrieving with Bar-code

One touch to find the cutting job out of those saved in the USB memory by scanning the printed Bar-code, while no need to connect to computer. Multiple jobs are processed automatically while production errors are eliminated.

Auto Fed System

Conveyor is applied for long seamless cutting / plotting operation.

The coordination of Gunner program, auto feeding system and CCD camera accomplishes fast and accurate nesting / contour cutting.

Parameters

| Model | GR7090F |

| Working Size on X Axis | 730mm (Non-contour Cutting) |

| 710mm (Contour Cutting) | |

| Working Size on Y Axis | Sheet Material: 910mm |

| Roll Material: Whole Roll | |

| Max.Media Width Applicable | 810mm |

| Applicable Media Thickness | ≤1.5mm |

| Applicable Media | PET, PVC |

| Method to Feed Media | Conveyor & Roll Media Bracket |

| Method to Fix Media | Vacuum Table |

| Max. Cutting Speed | 600mm / s |

| Max. Cutting Force | 600G / 5.8N in 8 Steps |

| Cutting Force Setup | Adjustable in Every 1G |

| Cutter Blade Diameters | Φ2.0mm |

| Cutter Blade Angles | 30°, 45°, 60° |

| Dotted Lines Cutting | Included |

| Drive | AC Servo |

| Mechanical Resolution | 0.0125mm |

| IOS | Win11 / 10/ 8 / 7 |

| Memory Buffer | 2MB |

| CAD/CAM Software | Windows Driver, SignWorkPro, CADtoPlotpro, Flexi, Cadlink ( Digital Factory v11) |

| LCD | English / Chinese |

| File Format | HP-GL, PLT |

| Port in Standard | USB, RS-232 |

| Registration Marks Recognition | CCD Camera |

| Power Input | AC 90-240v, 50-60Hz |

| Power Consumption | 2.2kw |

| Cutter Holder | 1 |

| QR Code Scanner | Included |

| Roll Media Bracket | Included |

| Floor Plan W-L-H | 1240 x 1800 x 1030mm |

| Package Size W-L-H | 1400 x 1600 x 1250mm |

| Gross / Net Weight | 305 / 260kg |

Brochure

DownLoad Brochure